Company

Our heart beats for toilet seats

"We create quality of life" - with our high-quality WC seats, our responsibility as an international employer and our environmentally friendly production.

Tyärk Dieckmann (Geschäftsführer Vertrieb und Marketing), Michael Huck (Holding Geschäftsführer Hamberger Industriewerke) und Ralf Schwaighofer (Geschäftsführer Produktion)

Hamberger Sanitary as one of the most innovative companies in Germany!

We have been named one of the top 100 innovators. This prestigious award recognizes companies that set themselves apart from others through outstanding innovative strength and pioneering developments. At Hamberger Sanitary, we have always relied on innovation as the key to success. Our dedicated employees strive every day to break new ground and push the boundaries of what is possible. This award is a recognition of their hard work and ingenuity. Being included in the Top 100 Innovators encourages us to continue on our chosen path and continue to set standards in our industry.

We see this as an incentive to continue developing innovative solutions that offer our customers real added value. We would like to thank everyone who has contributed to this success - our employees, partners and customers.

Together, we will continue to be at the forefront of innovation and actively shape the future.

Hamberger Sanitary worldwide

Our locations

The home of our company is Upper Bavaria. At our company headquarters in Rohrdorf, we have grown into what we are today: Europe's largest manufacturer of high-quality WC seats. With the areas of development, service, sales and marketing, the heart of our company has been beating here for over a century.

With our other locations in Bulgaria and China with more than a thousand employees, we have been able to adapt our production capacities to market requirements in recent years:

Rohrdorf, Germany

17.000 m² production area

200 employees

Research & development, product management, sales and marketing

Sevlievo, Bulgaria

74.000 m² production area

1,200 employees

First international production site since 2003

Kunshan, China

5.300 m² production area

60 employees

Since 2012 production site mainly for the Asian market

Cairo, Egypt

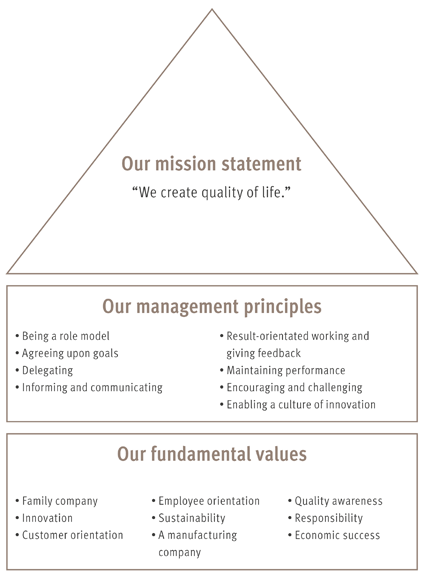

“We create quality of life”

Our mission statement

Our mission statement expresses the basis of our thoughts and actions: Because we create quality of life!

We are an important employer in our home region of Upper Bavaria. Through stable economic activity, we guarantee secure employment and thus make an important contribution to the economic prosperity of our employees. And this not only at our site in Rohrdorf, but also in Sevlievo, Bulgaria, and Kunshan, China.

As a responsible manufacturer of toilet seats, sustainable production is also close to our hearts. That is why we strive to produce and operate as sustainably as possible.

Highest quality without compromise - this is another pillar of our value system. We attach great importance to care and conscientiousness in the production of our toilet seats.

We see ourselves as a fair partner in society. We want to strengthen the common good and give economic impetus to our region.

Focusing on people and nature

Our understanding of sustainability

As medium-sized company we take our responsibility towards people and nature very seriously. The health and further development of our employees are matters close to our hearts. The basis of our attractive working environment is therefore formed by a wide range of training and further education measures, cooperation with regional fitness studios and environmentally conscious offers such as the JobRad. As a responsible employer, we are proud that our company health management system has already received the Gold Award from AOK Bayern.

At the center of our environmental management system is the continuous further development of our environmental performance in terms of ecologically sustainable and environmentally friendly production. Our long-standing certification according to ISO 14001 shows that we have already achieved great success in this area.

Sustainability through durability

We achieve this through smart comfort features and the highest-quality materials, which feel good, look good and make good hygiene easy. This high quality is reflected in the durability of our toilet seats, thus contributing to the conservation of resources.

We’ve always got our finger on the pulse

Our core strengths

We always have our finger on the pulse, we know what the latest trends are, and we work with the most up-do-date technology. This is how we manage to produce extraordinary and modern toilet seats that meet user requirements.

Our core strengths lie in the following areas:

- continuous development of construction and production methods

- complete product development from a single source – from the first idea to 3D-illustrations and prototypes right through to the finished product.

- CAD-supported construction and design for an extremely precise approach

- analysis according to the finite element method (FEM) for strength calculation and component optimization

- in-house rendering for perfect surfaces

- rapid prototyping for fast first parts

Professional expertise in every department

Our production chain

Our toilet seats are the result of extensive research and development, production that for the most part is fully automated, and uncompromising quality control in all production areas.

-

LOGISTIK

Thanks to our reliable, worldwide logistics network, we can guarantee fast order processing and short delivery times. At the same time, our quality standards by no means fall by the wayside: With standardized incoming inspections and material tests as well as the conscientious examination of documents relating to quality agreements, we succeed in ensuring the consistent quality of our products right from the start. Long-term business relationships with our suppliers are also a central aspect of our quality management in the area of incoming and outgoing goods.

-

PRODUKTION

As Europe's largest manufacturer of toilet seats and a family-run production company, we manufacture the components of our toilet seats largely independently and in-house. The focus is on our own press shop, the fully automated production of our SoftClose® dampers and our hinge production.

Our first-class WC seats are manufactured in defined and monitored processes. Fully automated processing in our modern press shop guarantees the highest product consistency and quality.

All the hinges we install in our WC seats also come from our own production. Certified stainless steel is processed into our high-quality hinges in elaborate chipping and bending processes. With more than 350 fastening solutions, our range is characterized by unique versatility and customized solutions. -

DAMPER PRODUCTION

Our high-quality SoftClose® dampers are the basis of our comfortable WC seats. They offer technical solutions for every requirement - in line with our extensive Hamberger modular system. Quality and durability are also the focus in the production of our dampers. That is why the technology is perfected in our in-house research and development department and produced in fully automated manufacturing. Uncompromising tests according to our own very strict quality standards ensure their longevity.

-

LABOR

For the production of our high-quality WC seats, we require flawless materials and product components. In our laboratory, we test these in various procedures. Our tests go far beyond the DIN standard and are additionally certified according to Norm Française (NF). In our modern laboratory, we ensure the quality of all individual components by means of standardized incoming inspections and material tests as well as independent tests of the material characteristics. We use reactivity testing to ensure the raw material quality of all materials used. In addition, automated tests of damper performance (torque curve), extensive process monitoring of the automatic lathe shop and fine measurements with our Keyence digital measuring projector take place. For full quality assurance, we carry out specific in-house tests.

-

PACKAGING

Our packaging department works at full speed every day - and in our plants in Germany, Bulgaria and China. This is how we manage to pack several thousand WC seats every day.

-

STORAGE LOGISTICS

To guarantee our customers the constant availability of our products, we keep over one million WC seats in stock. Thanks to sophisticated warehouse logistics, we thus guarantee high component availability and fast delivery of our WC seats. With our high-bay warehouses with thousands of shelf spaces, we use storage space sensibly and sustainably.